Products

Battery Welding

Interested

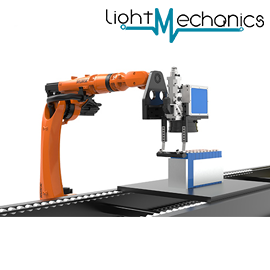

flashWELD battery welding systems comes with high quality laser, multi axis laser welding head with wobble option, Industrial chiller, panel AC, Fume Extractor, Class 1 enclosures with pneumatics, camera for weld positioning, post process weld inspection systems, XYZ gantry, conveyors to name a few.

For battery welding applications both CW (Continuous Wave) and QCW (Quasi Continuous Wave) lasers are used. The manufacturing or the joining needs are determined by the pack size, tab and terminal material along with the type and thickness of busbars. A clean understanding of application is required to implement the best laser welding solution suitable for the requirement.

Li-ion batteries are complex assemblies of multiple layers of several materials like copper, nickel, aluminium, nickel plated copper, stainless steel etc. in a wide range of thicknesses ranging from 0.10mm – 5mm. The manufacturing of such packs involves welding a large number of connections including joints between dissimilar materials. As batteries are manufactured at a very high rate, sometimes well over 10 per second, the use of resistance welders or mechanical fasteners is not always viable, resulting in laser welding becoming a technology of choice where matching cycle times becomes a crucial factor to be considered.

Advantages

High quality and fully reproducible welds

Minimized Thermal Heating / Heat Affected Zone (HAZ)

10X faster and reliable than other welding methods

High Weld Strength

Ability To Weld Dissimilar Metals

Suitable For Highly Conductive Metal Welding

Ultrafast Speed and Precise Welding Quality